ASSEMBLING

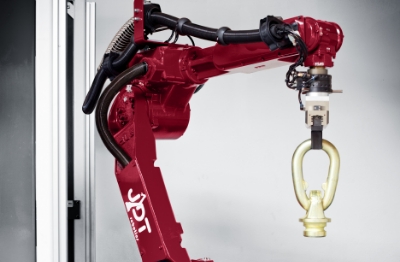

The assembly of components is a standard application for industrial robots. With the Flexible Robot Cell, we have developed a mobile and economical automation solution that can be used quickly and easily at different locations in manufacturing processes, including for assembling components.

UNBEATABLY FAST ASSEMBLY WITH THE FLEXIBLE ROBOT CELL - AT THE LOCATION OF YOUR CHOICE

"The fast assembly of components in large quantities is a standard application for industrial robots that is carried out in many manufacturing processes and at different locations."

Why use a robot for exactly one application when similar work processes take place at different production locations in different periods of time? With the Flexible Robot Cell, we use one robot unit for assembly processes at different production locations. Quickly dismantled, simply pushed to the new location by two people and reassembled, the compact Flexible Robot Cell can be used in a space-saving and variable manner at several production locations - not just for the assembly of individual parts.

If the corresponding assembly steps for the respective location are already programmed, the robot unit is immediately ready for use.

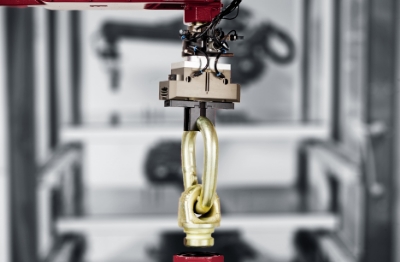

SAFE HOLDING OF THE WORKPIECE

The gripper, which is adapted to the workpiece, picks up the component to be assembled securely.

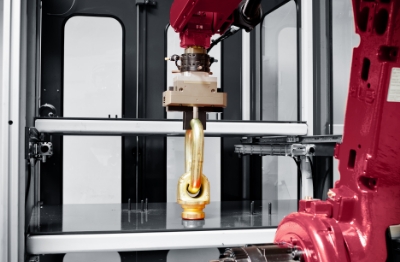

FAST TRANSPORT TO THE ASSEMBLY STATION

The control unit automatically calculates the fastest route for the robot arm from the workpiece holder to the assembly station.

PRECISE ASSEMBLY OF THE COMPONENTS

The components are assembled with pinpoint accuracy to ensure smooth assembly.