POWDER COATING

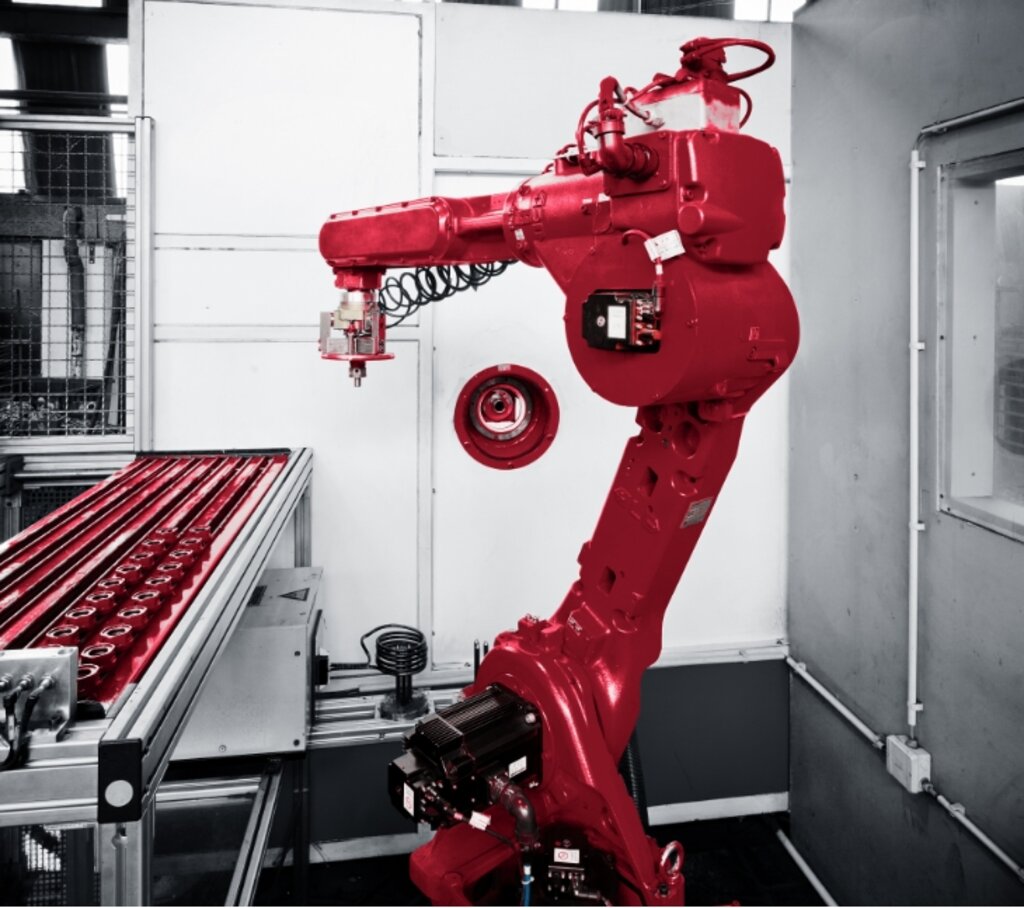

The Standard Robot Cell, which has been specially adapted for powder coating, not only guarantees a consistently high coating quality with optimum use of the powder material, the robot unit also meets the required explosion protection thanks to the specially designed non-conductive gripper.

SPECIAL POWDER COATING SOLUTION - THE STANDARD ROBOT CELL ALSO FOR SPECIAL APPLICATIONS

"Industrial robots can be used extremely flexibly and are therefore also suitable for the automation of very special work processes - such as powder coating a metal surface."

The use of the Standard Robot Cell not only guarantees a consistently high quality of coating with optimum use of the powder material, it also takes into account the safety requirements in the production process. The grippers of the robot arm have a non-conductive design specifically for this application, thus ensuring the required explosion protection in the coating process.

The robot takes the workpiece from the pallet, feeds it into the coating system and rotates it evenly while the powder is applied in the coating chamber. This ensures a homogeneous application of the powder and thus a uniformly thick coating of the highest quality - workpiece by workpiece.

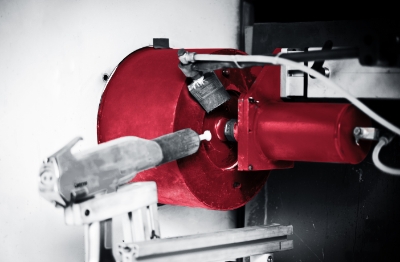

PRECISE POSITIONING IN THE COATER

The gripper guides the workpiece to the coater by the shortest route and always places it reliably in exactly the same position.

UNIFORM COATING OF THE WORKPIECE

The gripper rotates the workpiece evenly while a defined quantity of powder is applied.

QUICK PLACEMENT OF THE WORKPIECE

The robot reliably places the coated workpiece on a prepared base.