GRINDING A CHAIN LINK - AUTOMATION REDUCES HEALTH RISKS

"We use the Flexible Robot Cell to grind the forging burr of heavy chain links to relieve our employees."

At up to 6 kg for a forged chain link, the handling of large quantities places an enormous physical burden on the worker. In addition, the fine grinding dust produced during the machining process is an additional health hazard for those involved. By using the Flexible Robot Cell at the required location, we can not only prevent health hazards for our employees, but also significantly speed up the production process. The dust-insensitive Flexible Robot Cell can not only handle the heavy chain link faster and more safely without causing fatigue, it also achieves the same outstanding quality in the sanding result for every chain link.

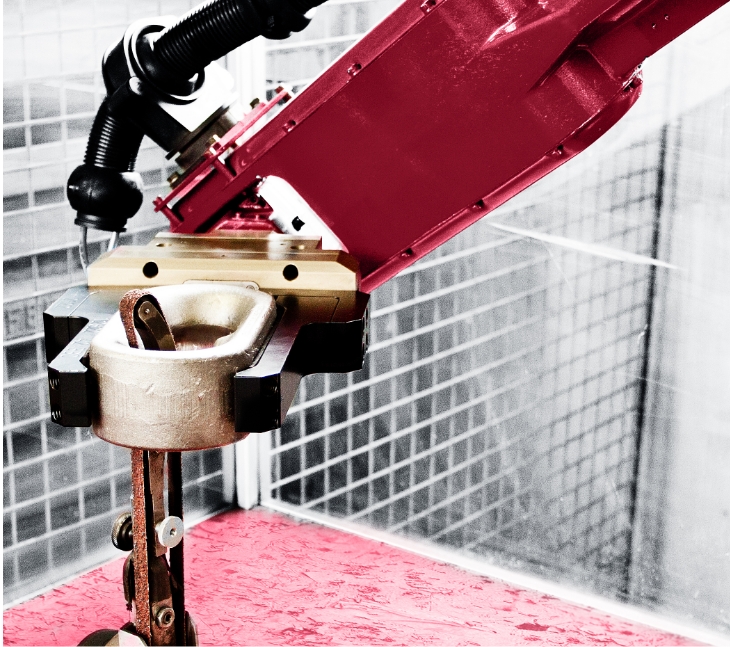

SECURE MOUNTING OF THE HEAVY CHAIN LINK

With its compressed air-controlled gripper, the robot picks up the heavy chain link without any problems and transports it reliably to the belt sander.

PRECISE GUIDANCE OF THE CHAIN LINK

With exactly the same movements, the robot arm guides the chain link evenly around the belt grinder and thus always produces the same high quality when removing the forging burr.

STORAGE OF THE MACHINED COMPONENT

The robot arm places the processed chain link precisely at the predefined position.