MILLING & DEBURRING

Time-consuming work processes, such as the milling of a blank, can be carried out particularly economically by an industrial robot. The Robot Cell control unit coordinates the optimally coordinated work steps between the connected machines via interfaces to the milling machine and the deburring machine.

MILLING AND DEBURRING WITH A ROBOT - THE ROBOT CELL COORDINATES COMPLEX WORK PROCESSES

"Time-consuming work processes such as milling a component can be carried out particularly effectively and economically by an industrial robot - especially in large quantities. The more work steps are performed by a robot, the faster the use of a Robot Cell pays for itself."

The loading of the milling machine and the subsequent deburring of the milling edges is carried out by just one standard Robot Cell. The numerous work steps are precisely defined in a program and stored in the Robot Cell's programmable logic controller. The milling machine and deburrer are connected to the Robot Cell's control unit via interfaces. Depending on the progress of the production process, it sends and receives signals from the connected production units and thus coordinates the optimally coordinated work steps of the robot, milling machine and deburrer.

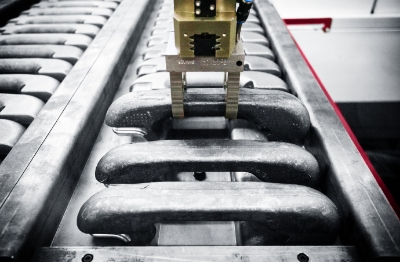

PRECISE POSITIONING OF THE MILLING MACHINE

The robot transports the blank to the milling machine by the shortest route and places the workpiece precisely in the clamping device.

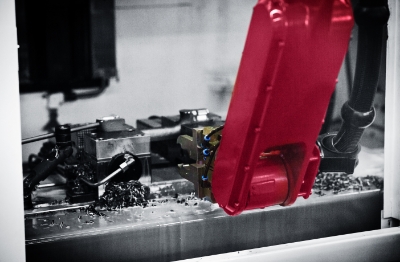

PRECISE DEBURRING OF THE MILLED EDGES

During the milling process, the robot picks up the milled component from the intermediate storage and deburrs the sharp milled edges. The robot arm guides the component precisely along the deburrer.

RELIABLE PLACEMENT OF THE WORKPIECE

After deburring, the robot places the workpiece on the pallet.