AUTOMATION SOLUTION FOR LINKING TWO WORK STEPS

"In order to make the production of our stop swivels more effective and economical, we link the turning and drilling operations in the production of the swivel body housing with an industrial robot."

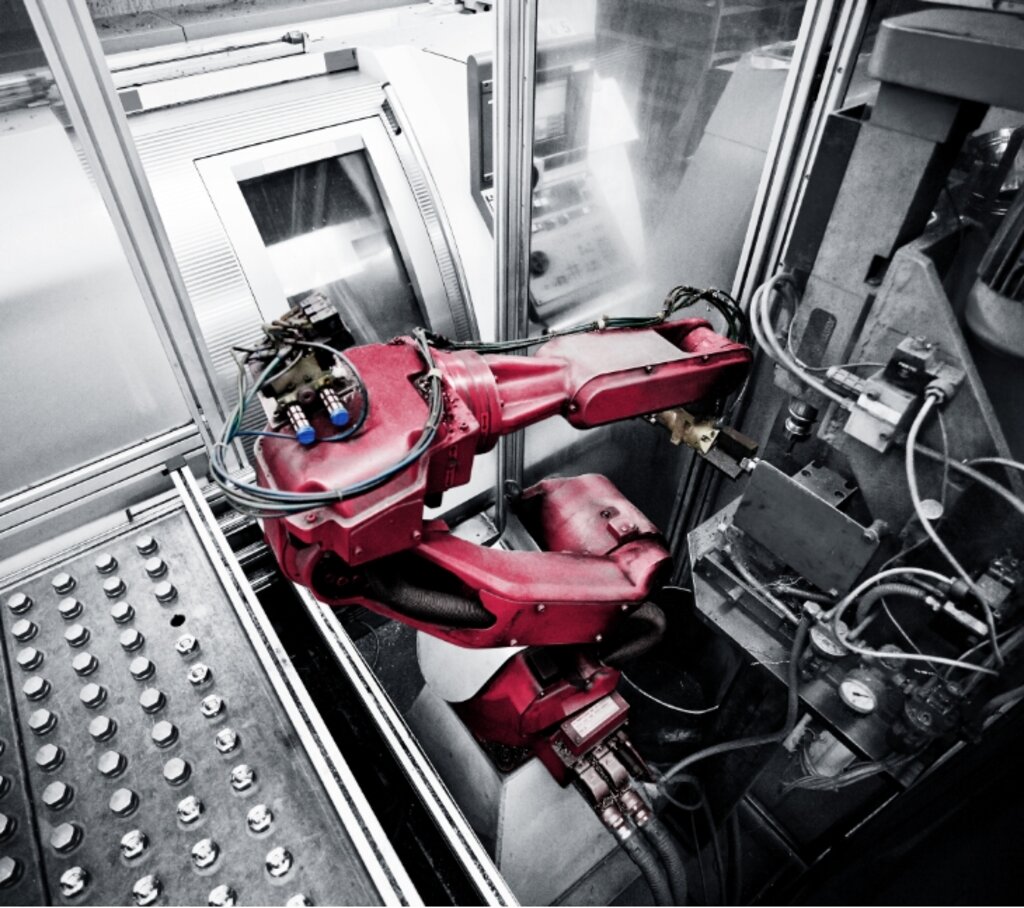

The stationary Standard Robot Cell with palletizing unit and side-mounted drilling device is placed directly in front of the turning machines within the robot's working radius. Equipped with a double gripper, it supplies the lathe with a vertebral body blank in the first work step and then directly loads the drilling machine with the vertebral body housing removed from the lathe. While the lathe produces the housing of the vertebral body, the drilling is carried out in parallel in the second work step. The finished vertebral body is placed on the pallet. The robot then picks up a new blank and moves to the waiting position.

SAFE RECORDING

OF THE ROHLING

The robot picks up the blank securely with a gripper specially adapted to the component.

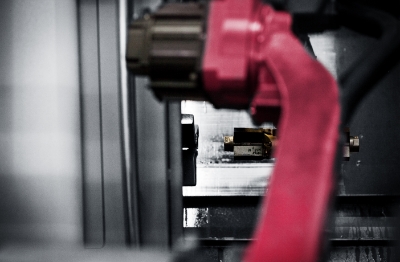

QUICK REMOVAL FROM THE LATHE

After turning, the robot cleans the workpiece with compressed air and removes it from the lathe's clamping device.

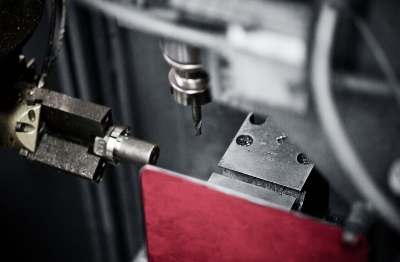

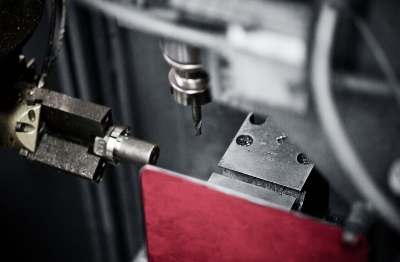

PRECISE EXECUTION OF THE BORE

a hole is drilled in the housing ...

FAST LOADING OF THE LATHE CHUCK

Once the turning process is complete, the robot removes the finished workpiece with a gripper, rotates the gripper by 180° and loads the blank into the lathe chuck via the second gripper.

RAPID REMOVAL OF THE WORKPIECE

... and the finished component is removed from the drilling jig.

RELIABLE PLACEMENT OF THE WORKPIECE

Finally, the robot places the processed component on the pallet and immediately picks up a new blank.