LOADING A LATHE

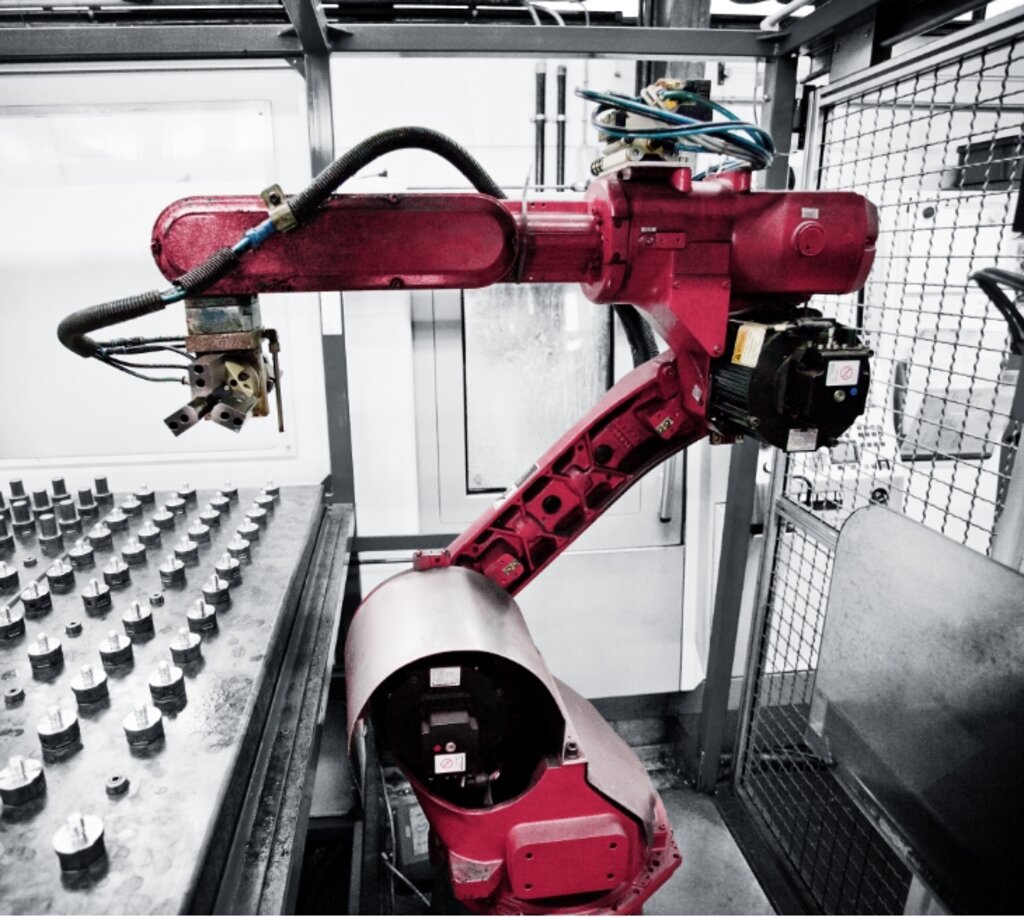

"The production of medium and high quantities, a simple and monotonous work step and the avoidance of unused worker time during the turning process predestine the use of an industrial robot for loading a lathe."

The standard Robot Cell with palletizing unit is permanently installed directly in front of the lathe. To optimize the work step, the robot arm is equipped with a double gripper, which enables the finished workpiece to be removed quickly and the lathe to be loaded with a blank immediately afterwards in a single work step.

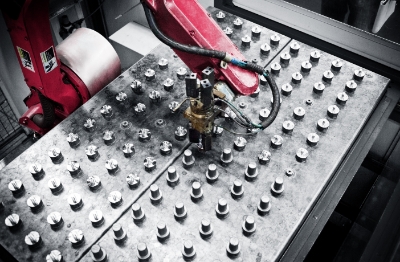

SECURE MOUNTING OF THE BLANK

The double gripper positions itself precisely above the blank on the pallet and picks it up with the 3-jaw gripper system controlled by compressed air.

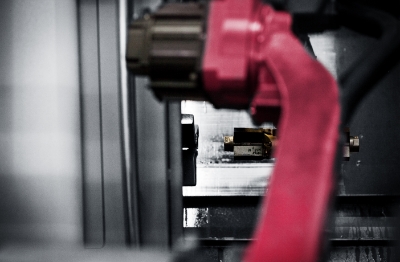

FAST LOADING OF THE LATHE CHUCK

Once the turning process is complete, the robot removes the finished workpiece with a gripper, rotates the gripper by 180° and loads the blank into the lathe chuck via the second gripper.

RELIABLE PLACEMENT OF THE WORKPIECE

The positions of the workpieces on the pallet are precisely defined. The finished turned component is placed exactly on the removal position of the blank.

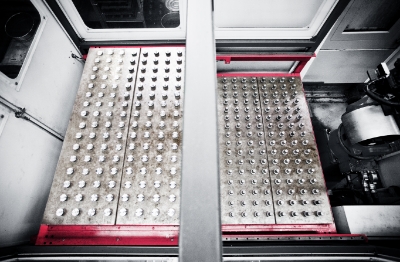

AUTOMATICALLY EXECUTED PALLET CHANGE

The Robot Cell's control unit registers when all the blanks on a pallet have been processed and automatically initiates a pallet change. The production process can continue without interruption.

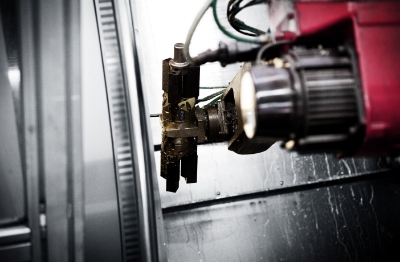

EFFECTIVE DOUBLE GRIPPER

The double gripper first removes the machined component with the free gripper and then loads the lathe chuck with the blank from the second gripper.